Analysis of Historic Post-Blast Data – A Novel Approach to Optimise Productivity and Profit while Maintaining Safe Working Conditions

GroundProbe’s Manager – Geotechnical, Peter Saunders

GroundProbe’s Manager – Geotechnical, Peter Saunders

GroundProbe’s Senior Geotechnical Engineer – Americas, Andrei Torres

Monitoring for slope stability in open-pit mines is a complex undertaking, vital not only for the economic feasibility of the site but also for the safety of those working in the area. It is generally understood that the quality of a rock mass in an open-pit mine may be subject to progressive deterioration over time as a direct result of vibration, successive blasting and other mining activity.

Quantifying the damage to rock mass can be difficult. A new method involving the analysis of historic Slope Stability Radar (SSR) data has the potential to set mines up for future success – assisting with early warning, optimisation of future blast design, machinery selection, forecasting production rates and maximising project profitability. For that purpose, the historic rock mass response to blasting was assessed using archived SSR data and the direct economic benefits quantified.

The Case Study: Mont-Wright Mine, Quebec

The Mont-Wright mine, located in regional Quebec and operated by ArcelorMittal Mining Canada (Figure 1), was identified as a case study for this new methodology. Historic SSR data was collected from between October 2011 and December 2012. The data was reprocessed, analysed and interpreted to assess for signs of significant historical damage caused as a direct result of production blasting.

Figure 1: Mont-Wright site localisation (Saunders et al, 2019)

Background and Methodology

The mine opened in the early 1970s and is comprised of several open pits, with the oldest being ‘Paul’s Peak’. In 2009, a geotechnical consultant proposed a large-scale pushback of the Paul’s Peak south pit wall to allow safe mining to recommence at the bottom of the pit – a location that saw a large slope failure in the 1980s. This plan was called the ‘Offload’ project, which started in 2011 but was suspended in 2012.

The Offload project resumed in 2017, and, prior to commencement of works, GroundProbe carried out a study to evaluate the long-term impact of blasting activity on slope stability during the period October 2011 to December 2012. The project included both a regional and local scale assessment of response to blasting, mining and environmental conditions.

The deformation data that was collected by the SSR systems during the assessment period was collected, processed and analysed in order to:

- evaluate the long-term regional deformation processes at a number of suitable control points;

- evaluate the local rock mass response to each of the individual blasts during the monitoring period; and

- assess the data for significant long-term deformation trends.

Lithology, Structural Geology and Slope Geometry

Paul’s Peak is primarily made up of four rock lithological units: the Iron Formation, a Mica Schist, Quartzite and Amphibolite. Weathering of the iron formation results in a heavily oxidised and leached condition, producing a friable texture which can be badly disintegrated.

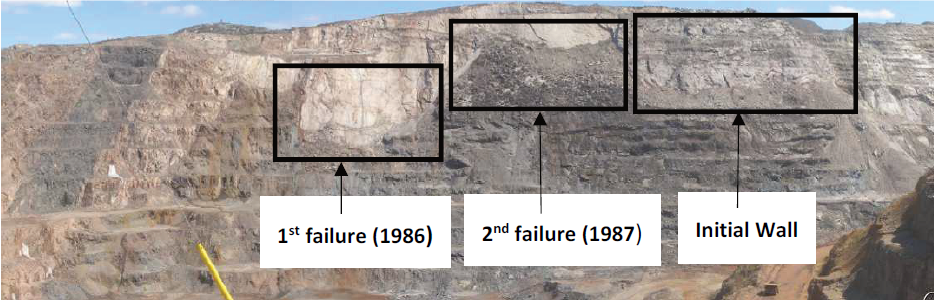

A major slope failure on the south wall of Paul’s Peak occurred in 1986/1987 (Figure 2). While the upper slope had been developed un-benched and failed along continuous structures parallel to the bedding, pre-splitting had been used in the iron formation rocks to develop a benched slope with safety berms. Regarding the pushback wall, an inter-ramp slope angle of less than 50 degrees was recommended to ensure overall stability.

Figure 2: Southeast wall of Paul’s Peak

Analysis

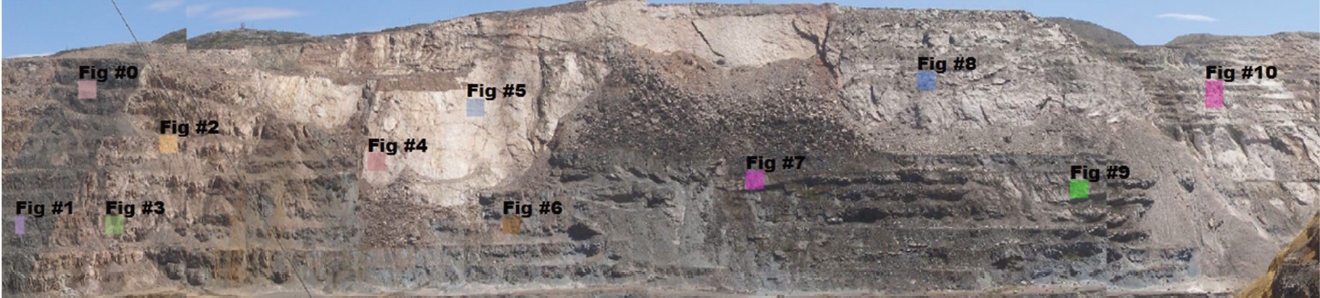

11 control points were selected based on a rigorous analysis and data ‘stitching’ process. The control points were used for the long-term deformation analysis – looking for disturbances in the deformation plots at stated blast times (Figure 3). The area that was directly disturbed by the blast was identified by using the deformation and coherence information from the SSR. Velocity analysis was also conducted to identify the time taken for the site to stabilise after each blast – the ‘time-to-stable’.

A major slope failure on the south wall of Paul’s Peak occurred in 1986/1987 (Figure 2). While the upper slope had been developed un-benched and failed along continuous structures parallel to the bedding, pre-splitting had been used in the iron formation rocks to develop a benched slope with safety berms. Regarding the pushback wall, an inter-ramp slope angle of less than 50 degrees was recommended to ensure overall stability.

Figure 3: Selected control points for long-term post-blast analysis at Mont-Wright mine

Results

The analysis identified that there was no clear evidence of significant progressive blast damage, either at a regional or local scale. Further, there was no increasing trend in the length of time-to-stable. Although there were a small number of moderate and significant post-blast damage cases, the risk of regional slope failure being triggered was considered relatively low.

The Economic Benefits

Increasing the size of blasts and reducing delays to re-enter the mine site has a two-fold economic benefit effect of reducing mining costs and increasing production rates. Based on the results of the deformation and damage assessments, the decision was made to modify the Paul’s Peak blast design – from 165.1m diameter holes with a depth of 7m, and 300kg as maximum allowable charge weights per delay to 216mm/311mm diameter holes with a depth of 14m and 550kg as maximum allowable charge weights per delay.

In terms of the maximum tonnage per blast, the tonnage of blasting material increased by 3.2 to 5.8 times compared to the blasts from 2011 to 2012 – measurably increasing the production rate and profitability of the Offload project.

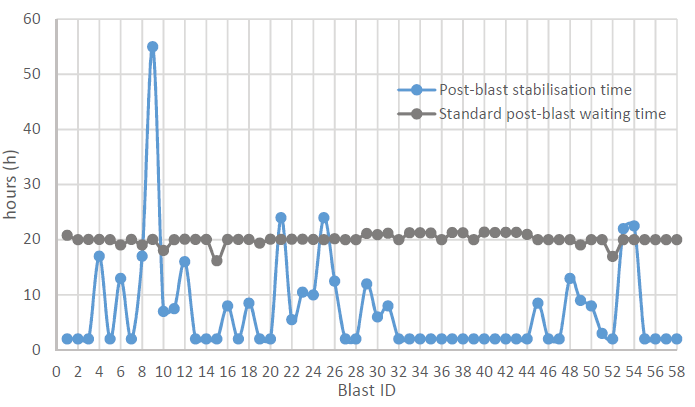

With regards to the post-blast re-entry time, without SSR the standard process for re-entry after an end-of-day production blast was to commence mining at 8am the next morning, after a visual inspection was carried out by a geotechnical engineer. With SSR however, post-blast stabilisation can be measured shortly after each blast event.

During blast activity in 2011 and 2012, a standard post-blast waiting time of around 20 hours was applied. Analysis of the historic SSR data identified that in 91% of cases the actual time-to-stable was significantly shorter. This suggested that SSR data could be used to both improve productivity by decreasing overly conservative delays, as well as effectively managing risks in the cases where stabilisation does take longer. Conservative estimates put the cost-saving of this procedural change at around $3 million over the monitoring period.

Figure 4: Curves of the standard post-blast waiting time and the post-blast stabilisation time

A Proactive Approach to Post-Blast Monitoring

It is clear from the analyses conducted that there are potential safety and economic benefits associated with careful assessment of historic slope stability radar data over time following progressive production blasting in an open cut mine.

The Mont-Wright case study shows us that alongside traditional vibration monitoring tools, this methodology can reduce an overly conservative blast design approach and justify a more aggressive and profitable mine design. By taking a proactive approach to quantifying damage – using historic SSR data and by conducting ongoing monitoring – safe work conditions can be maintained, mining processes can be optimised, and significant cost savings can be made.

Read More

This article is a summary of the paper Post-Blast Slope Stability Monitoring with Slope Stability Radar by P Saunders, JM Kabuya, A Torres and R Simon.. The paper was presented at the 2020 International Symposium on Slope Stability in Open Pit Mining and Civil Engineering on May 12, 2020.