GML (Convergence Monitoring)

HIGH RESOLUTION, SUB-MILLIMETRE SOLUTION

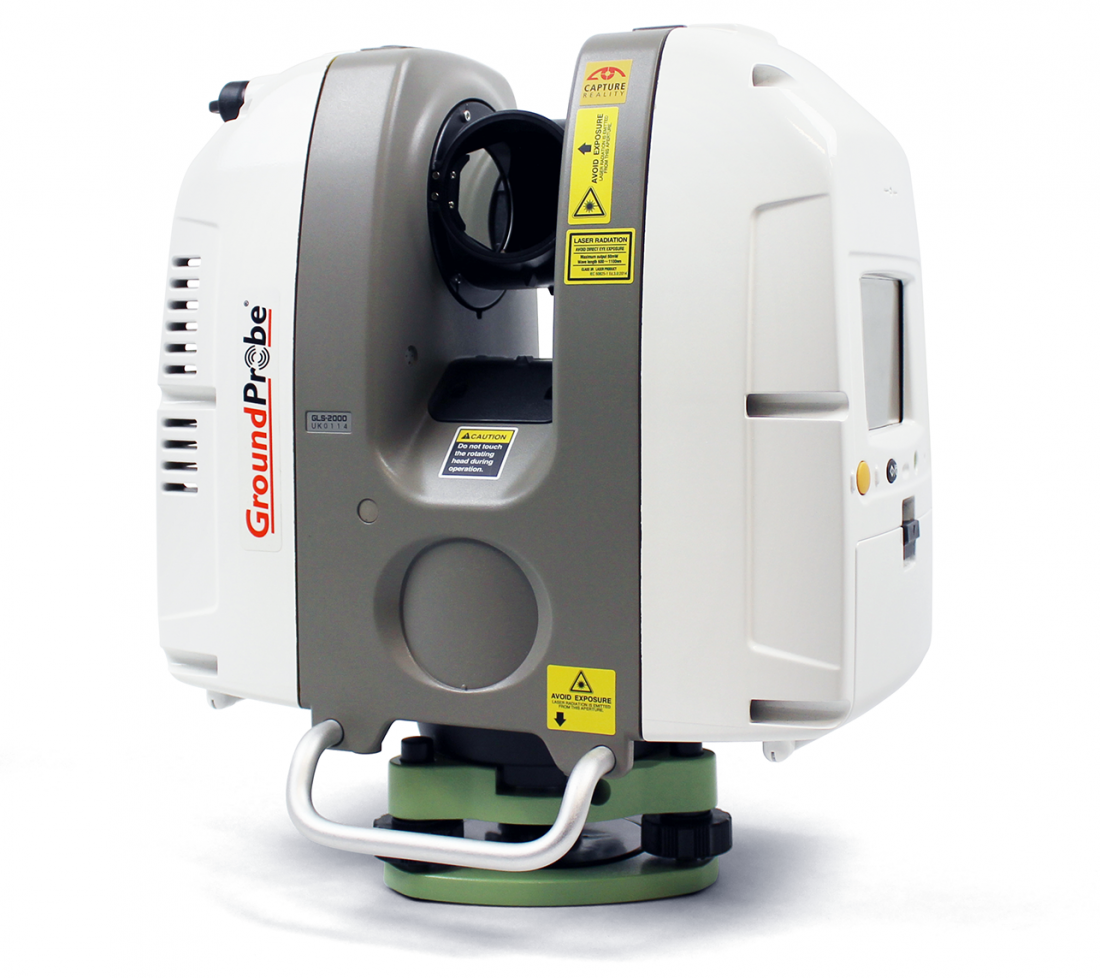

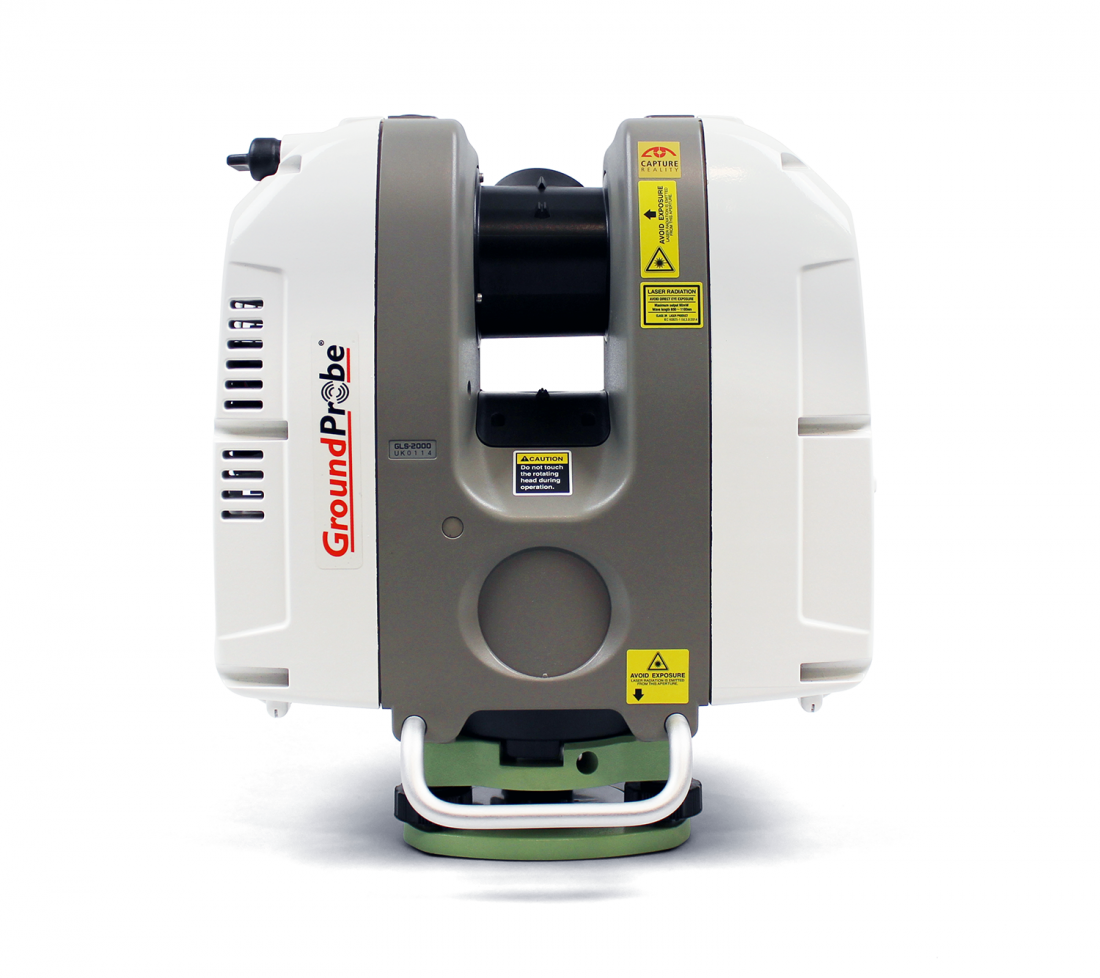

The GML – together with its Convergence Monitoring Module – is GroundProbe’s industry-disrupting underground monitoring solution. Capable of detecting rock and ground support movement with submillimetre accuracy, the GML offers a range of unprecedented features and benefits for underground monitoring.

The system can be deployed to meet the needs of any operation, at any stage. Users can choose continuous or periodic monitoring and deploy the device on a wall-mounted bracket (continuous monitoring).

In-built processing at the unit allows live data streaming to the surface, in real-time. Designed to reduce mechanical inaccuracies whilst allowing for maximum repeatability, the system rescans an area with high accuracy, with virtually no loss in precision between periodic or episodic continuous monitoring campaigns.

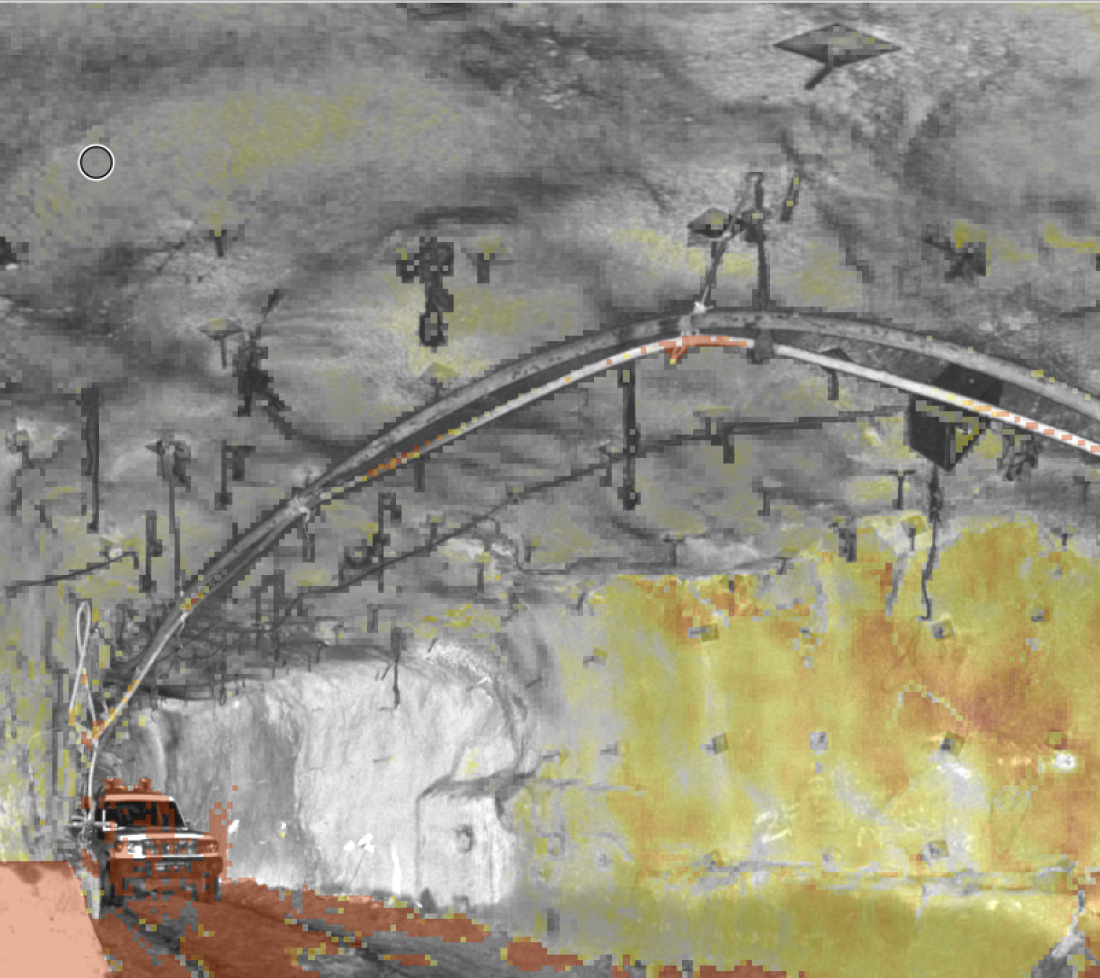

The GML computes high-density point cloud data in near real-time. Each point cloud, containing tens of millions of points, is co-registered with the data generated by the system. When visualised, the deformation heatmap is draped directly over the 2D front-view image or 3D point cloud, giving spatially co-located information. External models such as point clouds, meshes and string files can be imported to enhance the 3D visualisation.

Our proprietary data decimation processing algorithm produces scan file sizes typically 1% of the size of standard LiDAR data files, resulting in ultra-lightweight data of only 3MB per front-view scan. Data is streamed fast, even over low bandwidth connections, for multi-user remote visualisation and analysis.

Users can set a range of alarm parameters that are networked, stackable and accurate. Specifically developed for monitoring, alarms can be set on convergence, coherence, amplitude, velocity, inverse velocity, and our patented velocity ratio, allowing the user to correlate data to identify trends. They trigger on any device, anywhere in the world, in real-time.

With 360° x 270° coverage, the GML is perfectly suited to be deployed in any work area. Its all-encompassing horizontal movement can effortlessly monitor the breadth of a crusher chamber or long sections of wall, while its elevation angles ensure the floor of a drive and its backs or roof above can be monitored without difficulty. The scan area is completely customisable, so smaller targeted scans can be delivered according to user needs, faster.

When users require a quick but reliable reading, the GML can be deployed in fast scan mode. With the ability to take multiple readings rapidly, fast scans can be batch-processed to provide a marginally lower resolution snapshot of an operation in significantly less time.

Continuous monitoring data is processed underground and streamed through the mine network to the surface every few minutes. All critical metrics are transferred to the mine office for real-time monitoring. The fully-processed data can be accessed by multiple users at any one time, on-site or remotely, without the need to connect to a Virtual Network Computing server underground.

All data gathered by the system can be fully georeferenced. This allows users to export a georeferenced point cloud of a scan or specific highlighted areas. The data can easily be imported into complementary software, correlated to the exact location, ensuring the device fits seamlessly into any operation.

With near real-time automated data filtering, interference from mesh and other mining infrastructure is all but eliminated. Unlike interferometric-based underground radar technology, the GML sees between the mesh and metal reinforcement, eliminating noise which might otherwise obscure the real deformation occurring behind.

Product features and videos

| OPERATIONAL SPECIFICATIONS | ENVIRONMENTAL | |

|---|---|---|

| Scan Area (Coverage):

|

Deployment Options: Continuous, stand-alone |

Operating Temperature Range: -5°C to +45°C |

|

Acquisition Time: 360° x 80° (6 minutes) |

Data Size per Scan: 3MB |

Storage Temperature Range: -20°C to +60°C |

|

Convergence Measurement Accuracy: +/- 0.4 mm (0.01 mm Resolution Range) |

Power Options: Continuous, stand-alone Continuous, at-surface |

Environment Rating: IP54 (IEC60529), |

|

Range: Standard – 0.5m to 130m |

Downloads and Resources

Related Products

MonitorIQ® Enterprise Geotechnical Software

Designed and developed by geotechnical engineers for geotechnical engineers, MonitorIQ® ...

More