Monitoring solutions have a significant impact in open-cut mining environments where slope failures are often at a great risk. When operating in an open-cut mine environment, the monitoring of the site for slope or rock movements is vital to ensure the safety of employees and equipment, as well as operational efficiency. That’s why GroundProbe has developed a comprehensive suite of both predictive and reactive monitoring solutions, specifically designed for the demands of an open-cut mine environment. Customisable to any site and any specific need, explore our innovative and cutting-edge radars, monitoring stations and software today.

RGR-Velox

The RGR-Velox (Reactive Geohazard Radar) is a high-precision reactive monitoring and alarm system for tailings dam breaches. The RGR-Velox is the highest precision, fastest scanning and longest range doppler radar in the market, providing unrivalled confidence to alarm and alert when a tailings dam failure occurs.

Take a lookBlastVision®

BlastVision® provides actionable insights from blast activity that can be used to make informed decisions, ultimately driving productivity, improving safety and helping control the impact of blasting on the surrounding environment.

Take a lookSSR-Agilis

The SSR-Agilis is a standalone vehicle monitoring system designed to protect personnel and valuable equipment in active working areas of a mine site.

Take a lookSSR-Omni

The SSR-Omni is a full-coverage, high-resolution monitoring solution that delivers precise, actionable data.

Take a lookInSAR Service

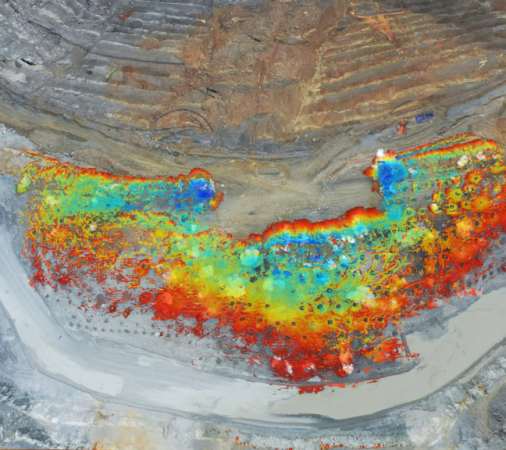

The GroundProbe InSAR Service, in partnership with 3vGeomatics (3vG), is an effective tool for monitoring and detecting surface movement. It uses satellite-based radars which conduct scans every time they pass over the mine site.

Take a lookSSR-SARx

Designed to identify long-range risks and hazards, the SSR-SARx is a long-range and high-resolution system for the monitoring of tailings dams. The SSR-SARx is a 2D Synthetic Aperture Radar (SAR) designed to detect even the smallest of movements over long periods of time.

Take a lookSSR-FX

The SSR-FX is a monitoring system designed to provide geotechnical peace of mind. An expert tool for risk and hazard identification, the SSR-FX is a 2D Real Aperture Radar (RAR) specialising in detecting movement across vast mine sites over a long period of time, even in non-critical areas.

Take a lookSSR-XT

A tactical and targeted solution, the SSR-XT monitors movement that poses a potential or immediate threat to mine slopes, tailings dams, and surrounding infrastructures in general. The strong precision of its 3D Real Aperture Radar (RAR) ensures that areas of concern are monitored in real-time to ensure safety-critical management of at-risk areas.

Take a lookAdvanced Radar Solutions for Open-Cut Mining Environments

GroundProbe has been developing industry-leading solutions for measuring and monitoring geohazards in open-cut or open-pit mining since 1993. Producing the highest quality technology, tools and mine monitoring systems for geotechnical engineers, mine site managers, mine operators and beyond. These open-cut mine monitors are strategically designed for advanced slope monitoring, ensuring that maximum site safety and efficiency is maintained at all times. Our wide range of open-cut mine monitors and radars is each designed with different purposes and features, allowing you to customise your monitoring solution to the specific needs and conditions of your open-cut mine site. Explore our full range of open-cut mine monitoring solutions, including:

- Slope Stability Radar (SSR) – As our most popular open-cut mine monitoring system, this radar can measure slope movement with sub-millimetre accuracy, even in harsh mining conditions. With a range of SSR options, you can choose the perfect monitor that works for your open-cut mining site. Choose between our SSR-FX, SSR-XT, SSR-SARx, SSR-OMNI and SSR-AGILIS models. For more information on each solution, check out the range of product pages.

- Blastvision – This advanced radar improves blast optimisation and post-blast analysis in open-cut pits, converting drone footage into actionable insights. With open-cut mines often performing frequent blasting, BlastVision® can help to minimise flyrock, optimise fragmentation, and reduce wall damage, leading to safer and more controlled operations.

- InSAR Service – Our InSAR service complements our range of on-site radar monitors by using satellite data to detect large-scale ground movement across the broader open-cut operation. This is particularly valuable for remote or difficult-to-access areas, dumps, or tailings zones surrounding open pits where traditional monitoring is limited.

- RGR Velox – This reactive geohazard radar ensures tailings dam safety near open-cut mines by providing real-time reactive alerts during sudden structural failures. In open-cut operations where tailings dams often border active mining zones, this system delivers critical early warning to protect workers and equipment in high-exposure areas.

To learn more about our products or how GroundProbe can create a custom mine monitoring solution for your site, make an enquiry or contact us today.

The Importance of Monitoring Open-Cut Mining Sites

Why is it so important to use a reliable monitor on open-cut mine sites? Like many other sites across the industry, open-cut mining operations are most complex and are highly susceptible to geotechnical challenges based on continuous ground movements. This means, as mine pits deepen and slope angles increase, the risk of slope instability, wall collapses, and geohazard events becomes greater. That’s why monitoring these environments isn’t just a best practice – it’s a critical component for site safety and operational efficiency.

Learn More About GroundProbe’s Open-Cut Mining Radars

At GroundProbe, we’ve engineered a comprehensive range of radar solutions that are specifically designed to tailor to the harsh and unpredictable conditions of open-cut mines. Each one of our open-cut mine site monitoring solutions plays a key role in addressing your unique geotechnical risks, helping you to monitor pit walls, haul roads, tailings dams, and working areas with unmatched accuracy. Explore the full range of highly accurate monitoring solutions at GroundProbe and get in touch with our friendly team of experts to learn more today!

Open-Cut Mine Monitoring FAQs

What types of monitoring systems are best suited for open-cut mining?

Open-cut mining sites often require the advanced insights provided by predictive and reactive monitoring systems in order to detect and mitigate evolving geotechnical risks. With GroundProbe’s slope stability radars (SSR), such as the SSR-FX and SSR-XT, we can offer real-time data on wall movement with sub-millimetre accuracy. For areas where radar is less effective, like vegetated slopes or waste dumps, our Geotech Monitoring Stations (GMS) provide the best solution for precision optical data used for long-term analysis. Explore our full range of open-cut monitoring solutions to meet the unique demands of your open-cut mining site.

How does radar monitoring improve slope stability in open-pit mines?

By using detailed and reliable radar systems, such as the SSR-OMNI and SSR-FX, mining sites can continuously scan high-risk slopes and walls to detect movement trends before failure or accidents occurs. With this type of early detection and detailed analysis, this allows geotechnical teams to have enough time to:

Identify instability early

Trigger alerts for evacuation or remediation

Reduce downtime due to unforeseen collapses

Make data-driven design adjustments to benches or ramps

As a result, real-time radar monitoring is a critical safety consideration in modern open-cut mine operations, without which it can cause significant safety risks and inefficiencies.

Can GroundProbe customise monitoring solutions for our mine site?

At GroundProbe, we’re all about making sure that your open-cut mining site has all the right equipment and data to operate effectively, efficiently, and safely. In order to achieve this, we specialise in site-specific monitoring strategies that can be tailored to your specific terrain, risk profile, and operational needs.

Our team will work closely with your geotechnical engineers to deploy the right combination of radar, optical, and software tools to maximise safety and data accuracy for your specific terrain. Contact us today for a consultation with our technical experts on how we can tailor a solution to your open-cut mine.