Monitoring and Measuring Squeezing Ground Conditions at Gosowong Gold Operation

MONITORING WEAK ROCKMASS

OVERVIEW

The Gosowong Gold Operation is located on Halmahera Island, about 2,450 kilometres northeast of the national capital, Jakarta.

It is an epithermal gold deposit with additional occurrences of silver. The mine uses a combination of cut-and-fill and long hole open stoping (LHOS) mining methods. Currently, PT. Nusa Halmahera Minerals operates two underground mines within the lease, Kencana and Toguraci Underground mines.

Gosowong Gold Mine is a low-stress mine with weak rock mass that commonly experiences squeezing ground conditions. Mines experience squeezing ground conditions when the orebody is in a weak rockmass, or when the mining-induced stress, is much higher than the strength of the rockmass. Mining in these conditions can be a slow and hazardous process.

Through convergence monitoring, areas of high risk can be identified and confident, well-informed decisions, key to the continued operation of the mine, can be made.

CHALLENGE

Gosowong’s site’s geotechnical team were already aware of the inherent risks associated with squeezing ground conditions at the mine and in 2019 selected GroundProbe’s GML technology to assist with monitoring.

By October 2020, significant damage was identified at an abandoned Diamond Drill cuddy (Grade Control Drilling). Regular inspections undertaken at the area of concern found weak ground with argillic alteration or mudstone clay. The area was considered unsafe to continue with drilling activity.

Management decided to barricade the area, excluding personnel and equipment with only restricted access permitted for monitoring and observation purposes.

SOLUTION

To help manage the risk, GroundProbe’s GML (Geotechnical Monitoring LiDAR) was deployed as the primary monitoring device and began measuring convergence in this area of concern. The GML – together with its Convergence Monitoring Module – is GroundProbe’s industry-disrupting underground monitoring station. Capable of detecting rock and ground support movement with submillimeter accuracy.

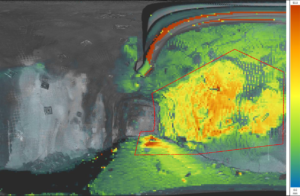

GML was complimented with GroundProbe’s intuitive visualisation software SSR-Viewer. SSR-Viewer provided the local geotechnical specialists with data to pinpoint movement hotspots by representing the data visually through a colour gradient heatmap draped over a photographic representation of the area, making the complex information more easily reportable.

RESULTS

Since the area had been allocated ‘No Entry’, the monitoring program was able to progress without interruption from mining activity.

Data was collected periodically over time by the geotechnical team.

“Using the GML LiDAR technology, we were able to observe and collect the data from a safe distance, unlike other monitoring devices such as tape extensometers which require direct exposure to the location over time.”

– Gosowong Geotechnical Group.

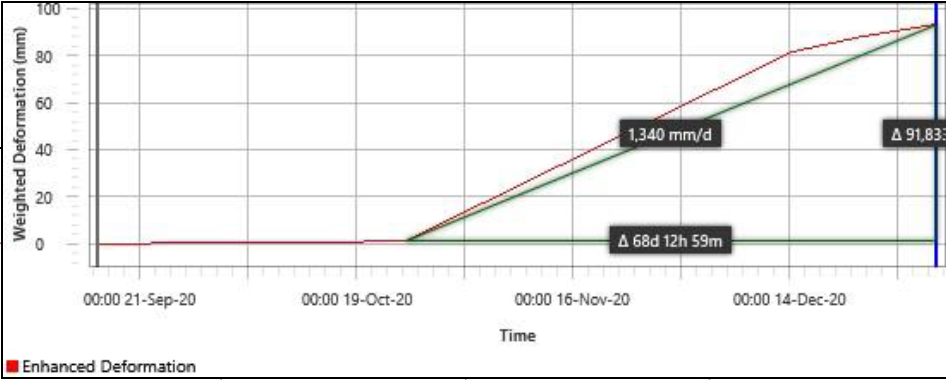

Floor heave was observed and directly measured and the right wall could be seen bulking out in the amplitude images with the software. The deformation heatmap showed the critical area experiencing significant convergence when overlayed on the amplitude image.

“The GML measured significant deformation in the right-hand wall and floor of approximately 0.40-1.34mm a day. Massive movement/yielding for the right-hand wall was estimated at approximately 6m depth, based on Hollow Bar displacement.

Initial trials demonstrated the highly accurate and precise nature of the GML as a real-time, underground monitoring solution for convergence. Although the convergence was previously recognised with a visual inspection, the high-quality data collected validated the conditions observed.”

– Gosowong Geotechnical Group.

It is important to effectively communicate geotechnical hazards and underground instability to crews and supervisors. An assumption of ground movement from visual inspection may lead to an inappropriate or costly response. GML data can be used to validate these assumptions.

“GML is one of the best solutions in the market for accurate monitoring of large-scale areas and the results may be used to understand the mechanism behind the movement so that the cause could be rectified or highlighted. Data collected by the GML is simple to explain and allows geotechnical engineers to highlight the area of concern to other relevant site personnel, increasing safety and geotechnical hazard awareness on site.”

– Rachmat Hamid Musa, Regional Geotechnical Manager – Asia.

GroundProbe is proud to have shared their world-class expertise in providing real-time solutions for measuring and monitoring geohazards to restore ongoing onsite mine safety.

GroundProbe is the most trusted brand for real-time geohazard monitoring. With a track record that speaks for itself, our fleet of cutting-edge technologies deliver the most precise and valuable data.

Image 1. Enhanced deformation graph showing movement of up to 1.34mm/day |

Image 2. GML Amplitude images showing floor and wall heave. |

Asia ContactRachmat Hamid Musa |

Media ContactJustin Brosnan |